CHECK YOUR BEARING

It’s a throw-away line that we all use – “you just need to check your bearings” – but what does it really mean to a trailer owner, and what do you need to be doing?

Boat trailer bearings are subject to perhaps the harshest treatment of all trailer bearings… ie potential exposure to water, especially seawater. Bearings in your wheel hub will start to rust if compromised by water ingress and lacking enough grease. While a bearing failure is the last step in the progression of very avoidable events, many people are caught off-guard when it happens. And even the process of failure follows steps that take it from an easily repairable breakdown event to a full-blown total collapse of the bearing. If you’re driving at the time, you risk the loss of a wheel and perhaps too if you’re unlucky, serious damage to the stub-shaft on the axle and potential consequences for other vehicles and road users.

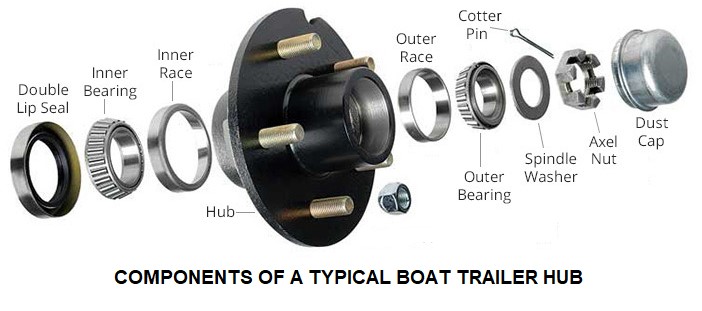

At some point as a trailer owner, it’s prudent to understand what your wheel hub consists of, how each component contributes to trouble-free towing and boating, and how effectively your maintenance regime is keeping all this in serviceable condition.

The diagram below expands on the mechanics. It’s a simple system held together by a single nut! The key ‘hardware’ items are the bearings and shaft seal… and the ‘software’ that allows them to function properly is the grease!

“Just check your Bearings” … has two very important elements.

1. It is the process of satisfying yourself that all components of the wheel hub are operating correctly, that the shaft seal is effective, and that the inner and outer bearings are adequately retaining and utilizing their applied grease.

2. It’s also the process of checking that what you think you’re doing …while checking and maintaining your bearings… is achieving what is both expected and needed!

Effective maintenance is the process of gathering information via observation, followed by taking appropriate action. Regular checks we recommend (every 2nd or 3rd time you’re intending to use your boat if used infrequently) will take just a few minutes per wheel and provide indicative information only.

The next level of checks that we recommend are done at least annually and will provide you with the factual information needed to understand and forecast the likely life of your bearings and what formal maintenance regime you need for your boat and your circumstances.

Frequent ‘Indicative Information’ checks.

A ‘back of hand’ temperature check of hubs after traveling to see if any is much hotter than the others, together with these wheel checks that take just a few minutes, will indicate whether or not you’re good to go on this occasion.

– Jack up a wheel and with both hands, try to wobble the wheel. Check that there is no movement.

– Spin the wheel and listen carefully to check there is no growling noise or you sense anything other than a very smooth and even rotation.

– Look at the inner edge of the hub and check that grease around the contact area between the seal and the shaft appears tidy and is consistent with the other wheels.

– Remove the dust cap or Bearing Buddy and visually check that the grease inside is not contaminated with water or dirt.

Planned ‘factual information’ checks.

At least annually after you first own your trailer, you need to dismantle the hubs and physically check the actual state of your bearings and greasing. This check requires the removal of the complete hub from the shaft, checking that the inner and outer bearings are being properly replenished with grease and that the seal is correctly functioning to keep the grease in and contaminants out.

We recommend you do this annually, and definitely before any long adventure, during which time both bearings and the hub should be cleaned and inspected. While some people prefer to replace all bearings and seals at this time, the bearings can be re-used unless there are signs of discolouring, pitting, or other deterioration on the bearing rollers and cones. The seal however is best replaced each time you remove a wheel hub – it’s very difficult to remove it without damaging it in the process.

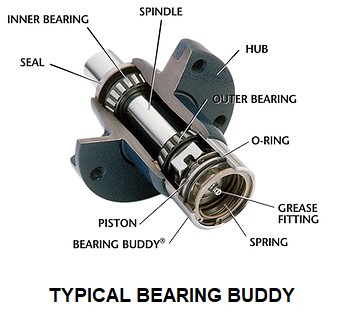

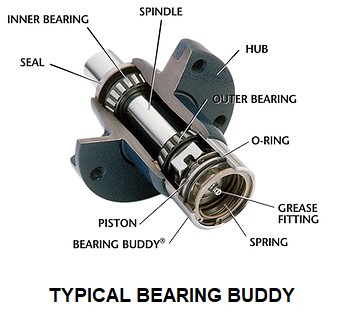

Caution – A Bearing Buddy is NOT a bearing greasing device!

A few pumps of grease into a Bearing Buddy every now and again does not qualify for ‘Checking your Bearings”. A Bearing Buddy (installation as pictured) is designed to maintain internal pressure inside the hub to stop water ingress. Consequently, trailers fitted with Bearing Buddies can fail the inner bearing because owners incorrectly presume BOTH the inner and outer bearings are being greased via the Bearing Buddy.

So “Check your Bearings” properly – and enjoy your boating!

Andrew van Ryneveld

Spitfire Boat Trailers SA

www.spitfiresa.com.au